MTA ROOF SCAN - EASY LEAK DETECTION

The MTA Roof Scan is an innovative leak detection device for use on all types of flat roofs.

Precise location of leaks is possible with the MTA Roof Scan without time-consuming preparations (e.g., removal of the gravel in the test area). All you need to carry out the test is the correctly attached earthing cable, which can be used to establish a voltage circuit to the electronics, and sufficient water to moisten the test area.

Testing is carried out by simply driving over the roof with the measuring systems. Based on the principle of the electrical conductivity of materials, this technology enables efficient leakage detection on roof surfaces without guess work.

SEE HOW IT WORKS

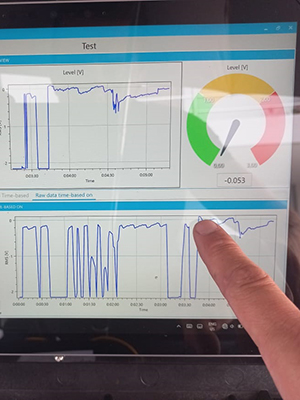

REAL-TIME MEASUREMENTS

The integrated software delivers the test data in real time to the display and offers the option of exporting test protocols as PDF files for your in-house reporting.

Handy design and the practical transport box make the MTA Roof Scan a reliable companion for leak detection missions. Thanks to the modern technology, even large roof areas can be inspected quickly and efficiently.

SUITABLE FOR ALL TYPES OF FLAT ROOFS

MTA Roof Scan has an innovative electromagnetic leakage measuring system for the precise location of leaking areas on all types of roof surfaces.

The highly developed technology enables the most accurate measurements for the most diverse types of roof structures, including:

- Cold and warm roofs

- Inverted roofs

- Green roofs

- Trafficable roofs

- Gravelled roofs

INNOVATIVE TECHNOLOGY IN THE SMALLEST SPACE

- Compact design of the electronic module in combination with a modern Windows tablet consequently form the basis for accurate measurements.

- Measuring data can already be viewed on the roof in real time. On the other hand, subsequent evaluation of the tests is also possible at any time through the integrated software.

- The practical design makes testing easy and efficient.

ONE PROBE – TWO MEASURING FUNCTIONS

The probe mounted on the measuring trolley is primarily used for surface testing. If the leaking area has been detected during the area test, this is clearly indicated in the measuring program.

To locate the defective area more precisely, you can carry out a point location of the leakage. On the one hand, you can remove the probe from the measuring trolley and use it for precise localisation by hand.

LEAK DAMAGE

SCANNING

LEAK PINPOINTING